Heating & Drying Ovens

Heating ovens and drying ovens are designed to precisely heat and dry samples at the same time. These ovens vary in size from 29 Liters to 1060 Liters and are suited for many lab settings including cosmetics and electronics testing.

Heating and drying ovens are appliances used in various industries and laboratories to perform heating, drying, and sterilization processes. These ovens provide controlled temperatures to facilitate specific reactions or remove moisture from substances without causing degradation.

Heating and drying ovens are versatile tools across industries, aiding in numerous processes where controlled heating or drying is essential.

Model Guide

UFTS

Forced Circulation Pass-Through Oven

This oven is the perfect material lock between the grey room and the cleanroom.

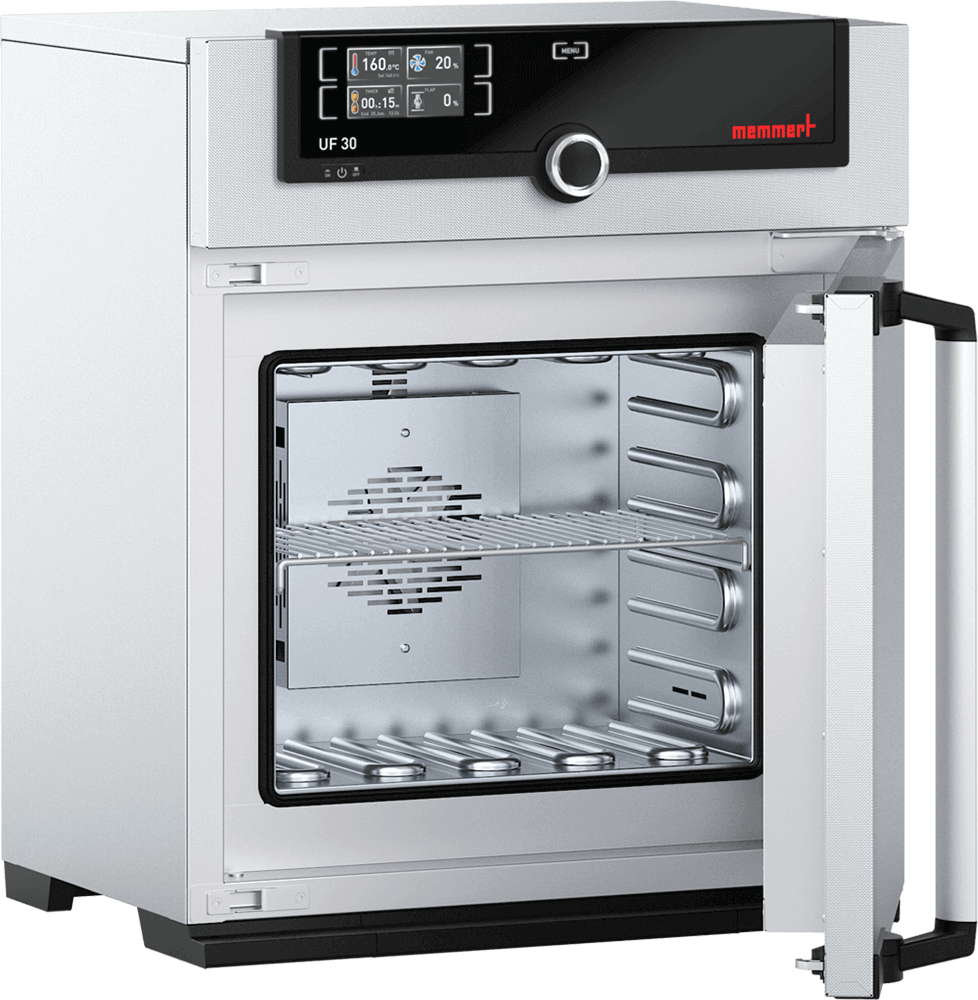

UF

Forced Air Convection Oven

Forced Air Circulation for excellent temperature uniformity via interior rear wall fan motor, variable speed control in 10% increments, or shut off completely.

UN

Natural Convection Oven

Memmert’s natural convection ovens are designed to reach temperatures up to 300°C efficient for complex processes with sensitive loads, or routine drying and sterilization tasks.

UNpa

Natural Convection Paraffin Oven

Designed for safety, high-precision temperature control of embedding medium like paraffin or wax.

VO

Vacuum Oven

Vacuum drying ovens with direct heating within each adjustable thermoshelf provides optimum temperature distribution and fast vacuum drying capability.

VOcool

Low Temperature Vacuum Oven

Low-temperature vacuum drying enables pharmaceutical or food labs to gently dry bacteria and starter cultures in the cooled vacuum oven VOcool.

Heating and Drying Ovens From Memmert

Quality and sustainability go hand in hand. Part of Memmert’s corporate strategy is environmental awareness and producing equipment that is energy efficient and durable. Actions Memmert has taken to protect the environment include using recyclable stainless steel and using materials that are environmentally friendly in production.

Laboratory Uses for Heating and Drying Ovens

Heating and drying ovens have a variety of uses in laboratory settings. They provide a controlled environment for heating, drying, and sterilizing samples and equipment. Our ovens’ ability to control temperature and atmosphere plays a critical role in many laboratory applications including:

- Drying: Drying ovens are used to remove moisture from samples and equipment.

- Sterilization: Heating ovens are used to sterilize equipment and samples by killing any microorganisms present.

- Curing: Our ovens can be used to cure resins, composites, and other materials.

Digital Heating and Drying Ovens with Programmable Temperatures

With the help of AtmoCONTROL, programming one of the heating and drying ovens can be done by mouse or touchpad on your laptop. Each oven has high-temperature connectors on the rear of the appliance, allowing for single-phase power connection according to country-specific systems and IEC standards. Adjustment of three calibration values for temperature and additional specific parameters can be done directly on the digital control screen.

Frequently Asked Questions About Heating & Drying Ovens

- What kind of metals can Annealing ovens heat?

- Annealing ovens are used to heat a wide range of metals in order to change their physical properties, such as their strength, ductility, and corrosion resistance. Some common metals that can be annealed in an oven include steel, aluminum, copper, brass, and titanium. The specific temperature and duration of the annealing process depend on the type of metal and the desired properties.

- What are the advantages of using a vacuum oven?

- Vacuum ovens can speed up drying and curing processes, reduce the risk of contamination, and allow for the use of lower temperatures compared to a standard oven.

- What is the difference between a convection oven & conventional oven?

- Convection ovens use a fan to circulate hot air around the oven chamber, which helps to evenly cook and brown food. In contrast, the heat in a conventional oven is not circulated and may be less evenly distributed.

Have a different question? Contact us today to find an oven to suit your needs.

Memmert Ovens: software & features

Memmert heating and drying ovens have accessories and special options to suit your lab. We can adjust or add certain features including:

- Entry ports

- Extended overtemperature protection

- Interior lighting for observing loads

- Telescopic trays

- Stacking frames

- Heating and cooling temperature ranges

- Gas concentration variations (oxygen, carbon dioxide, nitrogen)

Applications for Memmert ovens

Memmert drying ovens are used in labs, factories, commercial kitchens and more for a variety of uses:

- Annealing

- Dehydration

- Decarboxylation

- Degasification

- Sterilization

Programmable Lab Equipment

Our products are equipped with AtmoCONTROL technology that has programming functions depending on which display you select:

![]()

SingleDISPLAY and TwinDISPLAY

- Manage and organize data

- Save log files in several formats

- Monitor up to 32 devices online

- Automatic alarms sent to your email when conditions are out of spec

![]()

Additional features with TwinDISPLAY

- Archive of ramps and program sequences

- Real-time view of program sequences

- Loops can be inserted within a temperature control program at any place

- Download and manage programs via Ethernet or USB