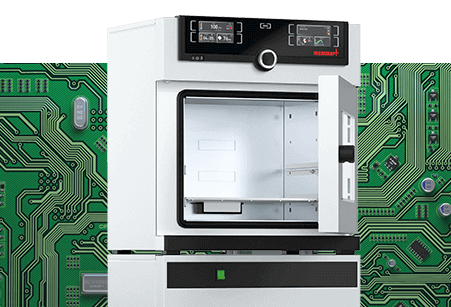

Vacuum Ovens VO

Vacuum ovens are used to effectively remove moisture, gas and other volatile chemicals while preventing reactions. Our vacuum ovens have been trusted in the manufacturing of implantable medical devices, packaged food products, essential oils, semiconductors and epoxies.

Model Guide

VO

Vacuum Oven

Vacuum drying ovens with direct heating within each adjustable thermoshelf provides optimum temperature distribution and fast vacuum drying capability.

Accelerated drying with intelligent vacuum control

Memmert’s vacuum ovens feature an exclusive vacuum capability for rapid, efficient drying of large batches. The pressure is intelligently oscillated between two setpoints, quickly introducing large volumes of dry air to absorb moisture before vacuum extraction. The innovative technology significantly reduces processing times compared to conventional vacuum ovens.

Industrial, food processing and pharmaceutical companies choose Memmert vacuum ovens to achieve shorter heating and processing times, aluminum thermoshelves and precise temperature control. Features include:

- Temperature range up to +200 °C

- Vacuum control range: 5 mbar up to 1100 mbar

- 3 model sizes (29 to 101 liters volume)

- 1 model variant: TwinDISPLAY (PLUS)

- Vacuum pump (PMP) sold as an accessory

- Inert gas connection for VO 49 & 10

Advanced Vacuum Ovens for Delicate Applications

Memmert’s vacuum ovens are ideal for curing processes and pressure testing in medical, aerospace and engineering applications involving paper, textiles, pharmaceuticals, ceramics, rubber and more. Vacuum ovens kill pathogens, rid chemicals and eliminate moisture without damaging sensitive materials.

Unparalleled Temperature Uniformity with Memmert Direct Heating

Memmert ovens utilize Multi-Level Heating and Sensing with adjustable shelves and separate sensors to guarantee precision across every position. Direct contact between the shelves and workload eliminates heat loss for shorter drying times. Intelligent circuits instantly adapt to different loads and moisture levels to maintain set temperatures throughout the process. Individual shelf calibration enables unmatched uniformity.

Energy-Efficient Vacuum Ovens

Memmert is committed to protecting the environment by developing energy-efficient products and green lab equipment, such as the Vacuum Oven. Vacuum Ovens by Memmert reduce drying time by 70% with the speed-controlled vacuum pump accessory, eliminating unnecessary energy consumption. Built with a direct heating system that maintains a constant temperature, Vacuum Ovens also minimize energy waste through heat loss. Memmert’s climate-friendly products save energy, resources and the environment.

Digital Vacuum Ovens with Programmable Software

All Memmert digital lab equipment is developed to be reliable and intuitive for the user. Easily program the Memmert Vacuum Oven via AtmoCONTROL on a computer or touchscreen, or utilize the Vacuum Oven’s interfaces and integrated data loggers to access even more options for programming and documentation. For employing these features remotely, every Generation 2021 product has an Ethernet interface that allows for access and control from anywhere in the world. Memmert Vacuum Ovens are programmed to be precise, efficient and trusted by pharmaceutical industries for removing chemicals, manufacturing medical devices and more.

Memmert Vacuum Ovens: Designed for Reliability

Engineered for safety-critical processes, Memmert vacuum ovens deliver exceptional performance:

- Intuitive interface for ease of use

- Durable stainless steel construction, inside and out

- Advanced heating technology ensures precision

- Extensive programming and documentation options

- Worldwide 3-year warranty

With expertise in vacuum drying, Memmert optimizes every detail to facilitate your critical processes. When consistency, quality and process control are priorities, our ovens provide the solutions you need.

Memmert Vacuum Oven FAQ

1. What temperature range can the ovens achieve and what is the vacuum control range?

The temperature range goes up to +200 °C and the vacuum control range is from 5 mbar up to 1100 mbar.

2. How many model sizes are available, and what are their volumes?

There are 3 model sizes available, with volumes ranging from 29 to 101 liters.

3. How does the accelerated drying with intelligent vacuum control work?

The pressure is intelligently oscillated between two setpoints, quickly introducing large volumes of dry air to absorb moisture before vacuum extraction. This innovative technology significantly reduces processing times compared to conventional vacuum ovens.

4. What is Multi-Level Heating and Sensing, and how does it benefit temperature uniformity?

Multi-Level Heating and Sensing uses adjustable shelves and separate sensors to guarantee precision across every position. Direct contact between the shelves and workload eliminates heat loss for shorter drying times. Intelligent circuits instantly adapt to different loads and moisture levels to maintain set temperatures throughout the process.

5. How much energy can be saved using the vacuum ovens?

The vacuum ovens can reduce drying time by 70% with the speed-controlled vacuum pump accessory, eliminating unnecessary energy consumption. The direct heating system minimizes energy waste through heat loss.

6. What software is used to program the ovens?

The ovens can be programmed via AtmoCONTROL on a computer or touchscreen. They also have interfaces and integrated data loggers for additional programming and documentation options.

7. Can the ovens be controlled remotely?

Yes, every Generation 2021 product has an Ethernet interface allowing access and control from anywhere in the world.

Programmable Lab Equipment

Our products are equipped with AtmoCONTROL technology that has programming functions depending on which display you select:

![]()

SingleDISPLAY and TwinDISPLAY

- Manage and organize data

- Save log files in several formats

- Monitor up to 32 devices online

- Automatic alarms sent to your email when conditions are out of spec

![]()

Additional features with TwinDISPLAY

- Archive of ramps and program sequences

- Real-time view of program sequences

- Loops can be inserted within a temperature control program at any place

- Download and manage programs via Ethernet or USB