Hemp Drying Ovens

The use of heating/drying ovens and vacuum ovens for the hemp and cannabis industry has exploded across the United States. Vacuum ovens are a faster and safer way to complete the cannabis extracting process.

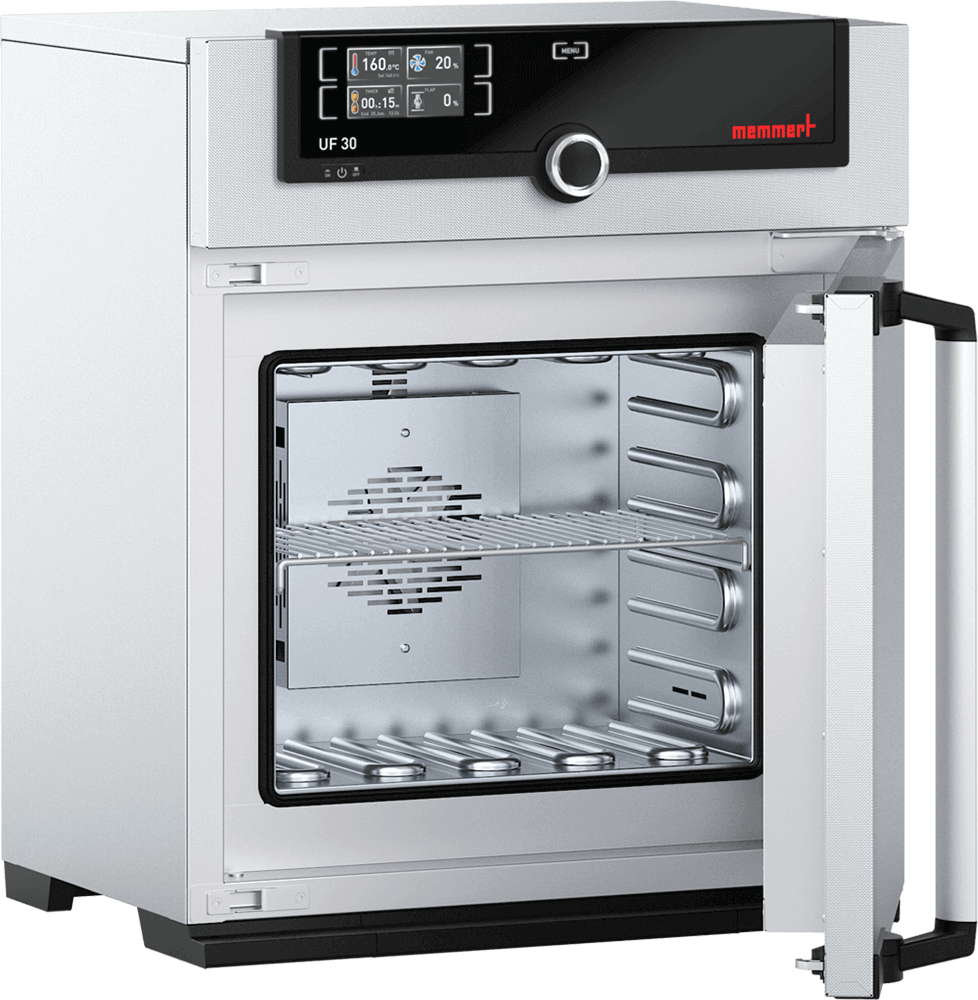

Hemp drying oven

Hemp drying ovens remove moisture from plants and flowers, allowing for the preservation of hemp plants and flowers by drying them after a harvest. Using a hemp drying oven increases consistency, speeds up production times to increase profits and preserves the potency and quality of plants to deliver quality products to consumers. In some states, a specific moisture content must be achieved before products in the hemp and cannabis industries are processed or sold.

Model Guide

UF

Forced Air Convection Oven

Forced Air Circulation for excellent temperature uniformity via interior rear wall fan motor, variable speed control in 10% increments, or shut off completely.

UN

Natural Convection Oven

Memmert’s natural convection ovens are designed to reach temperatures up to 300°C efficient for complex processes with sensitive loads, or routine drying and sterilization tasks.

VO

Vacuum Oven

Vacuum drying ovens with direct heating within each adjustable thermoshelf provides optimum temperature distribution and fast vacuum drying capability.

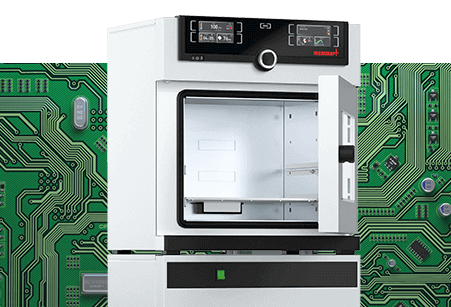

Programmable Lab Equipment

Our products are equipped with AtmoCONTROL technology that has programming functions depending on which display you select:

![]()

SingleDISPLAY and TwinDISPLAY

- Manage and organize data

- Save log files in several formats

- Monitor up to 32 devices online

- Automatic alarms sent to your email when conditions are out of spec

![]()

Additional features with TwinDISPLAY

- Archive of ramps and program sequences

- Real-time view of program sequences

- Loops can be inserted within a temperature control program at any place

- Download and manage programs via Ethernet or USB