Pre and Post Bake Ovens

Post-bake ovens are used to reduce dry time and ensure full adhesion of paints and coatings to produce strong, high-quality products. Post-bake ovens are used to cure paints and coatings onto materials to improve the durability of painted and coated products.

Model Guide

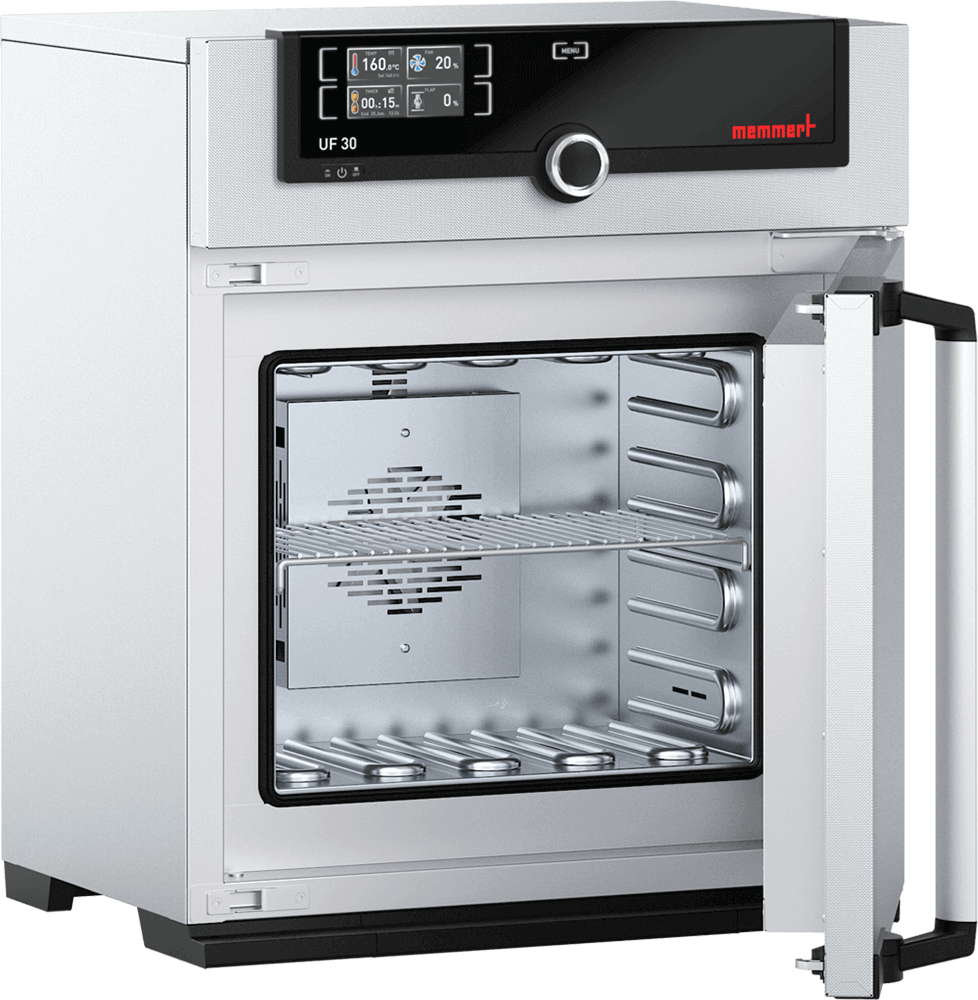

UF

Forced Air Convection Oven

Forced Air Circulation for excellent temperature uniformity via interior rear wall fan motor, variable speed control in 10% increments, or shut off completely.

UN

Natural Convection Oven

Memmert’s natural convection ovens are designed to reach temperatures up to 300°C efficient for complex processes with sensitive loads, or routine drying and sterilization tasks.

Benefits of Pre-Bake Ovens

Using a pre-bake oven makes materials more durable and easier to work with. When pre-baked materials are used with paints, coatings and composites, solvents and moisture that otherwise would have affected the quality or adhesion properties in the selected materials are evaporated. Using pre-bake ovens improves the chemical resistance, leveling and flow of heated materials to create a better product.

Benefits of Post-Bake Ovens

Post-bake ovens enhance baking efficiency by providing an additional stage for finishing products. They ensure uniform and consistent color, texture, and taste of baked goods through controlled heat and ventilation. With post-bake ovens, bakers can achieve professional-quality results, improve productivity, and meet customer demands effectively.

Memmert USA has the perfect pre and post-bake ovens for your next project. Our ovens come with the option for programmable cycles with TwinDISPLAY and are almost exclusively stainless steel inside and out. Our team will work with you to find the perfect oven for your next project.

Programmable Lab Equipment

Our products are equipped with AtmoCONTROL technology that has programming functions depending on which display you select:

![]()

SingleDISPLAY and TwinDISPLAY

- Manage and organize data

- Save log files in several formats

- Monitor up to 32 devices online

- Automatic alarms sent to your email when conditions are out of spec

![]()

Additional features with TwinDISPLAY

- Archive of ramps and program sequences

- Real-time view of program sequences

- Loops can be inserted within a temperature control program at any place

- Download and manage programs via Ethernet or USB