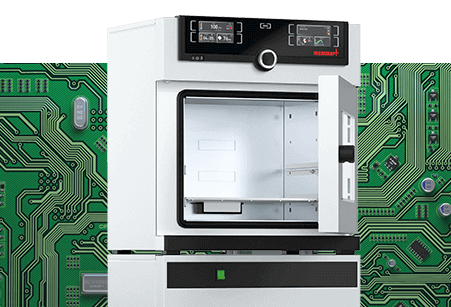

Stress Relieving Oven

Stress-relieving ovens are used to heat and cool metals at specific speeds and temperatures to increase the metal’s resistance and durability and to relieve internal stresses developed in the metal during the manufacturing process.

Stress-Relieving Oven Benefits

A stress-relieving oven strengthens metals to resist cracking, deformation, distortion and premature wear. The heating and cooling functions of stress relieving ovens help ensure proper fit and function of metal components in their applications and save money and resources by reducing the need for re-work following the production process. Stress-relieving ovens can make metals easier to work with, longer-lasting and more reliable for the manufacturing industry.

Memmert’s stress-relieving ovens are designed to uniformly heat samples. Our ovens can be found in the heat-treating processes within the aerospace and automotive industries for the processing of steel, aluminum, titanium and various other products. Memmert stress-relieving ovens can reach temperatures up to 300°C and have models available that are up to 1060 liters in volume.

Model Guide

VO

Vacuum Oven

Vacuum drying ovens with direct heating within each adjustable thermoshelf provides optimum temperature distribution and fast vacuum drying capability.

Programmable Lab Equipment

Our products are equipped with AtmoCONTROL technology that has programming functions depending on which display you select:

![]()

SingleDISPLAY and TwinDISPLAY

- Manage and organize data

- Save log files in several formats

- Monitor up to 32 devices online

- Automatic alarms sent to your email when conditions are out of spec

![]()

Additional features with TwinDISPLAY

- Archive of ramps and program sequences

- Real-time view of program sequences

- Loops can be inserted within a temperature control program at any place

- Download and manage programs via Ethernet or USB