Annealing Plastics

Annealing plastics is the process of heating the plastic until it's soft enough to flow freely. From here, it is placed in molds to take shape, where it will later slowly cool. This process helps reduce internal stress on the plastic and creates stronger products with a better finish.

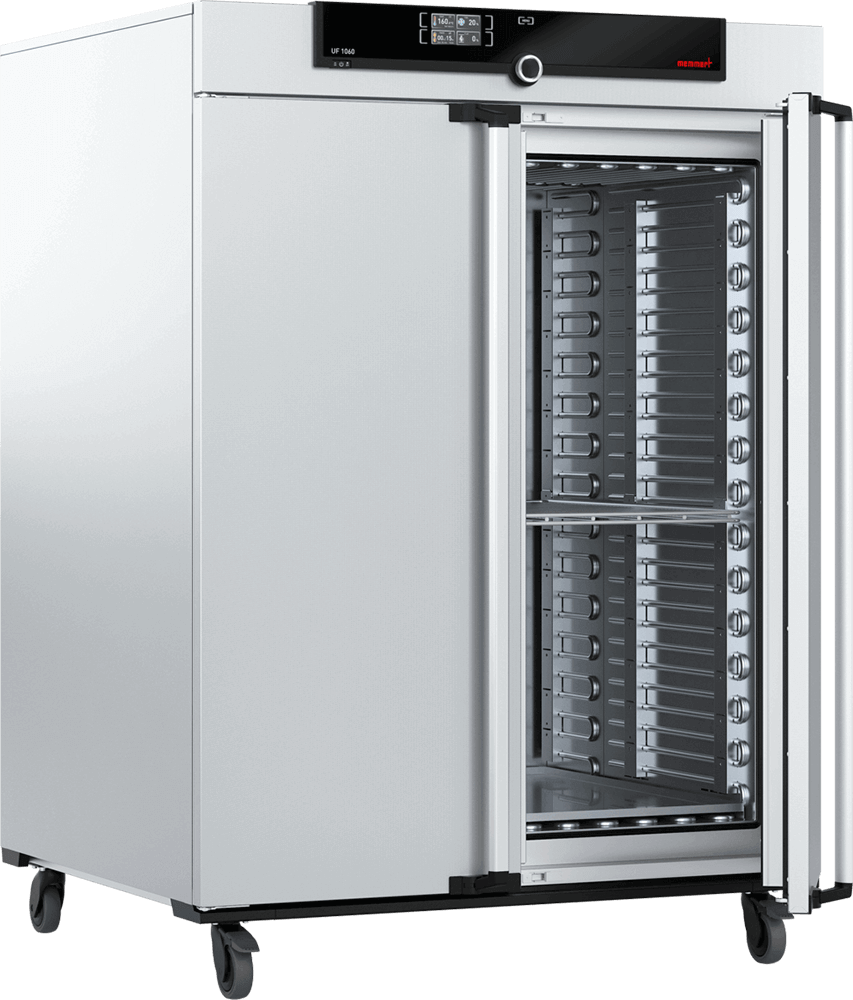

Ovens for Annealing Plastics

Memmert annealing ovens for plastics come in stainless steel, which is scratch-resistant, hygienic and robust for an everlasting design. The annealing oven from Memmert has adjustable parameters for temperature (Celsius and Fahrenheit), air flap position, program time, time zones and daylight saving time. The timer is a digital backward counter with a target time setting, which is adjustable from 1 minute to 99 days. Memmert annealing ovens can range in size from 32 to 1060 liters in volume and have maximum attainable temperatures of 300°C/572°F.

Model Guide

UF

Forced Air Convection Oven

Forced Air Circulation for excellent temperature uniformity via interior rear wall fan motor, variable speed control in 10% increments, or shut off completely.

UN

Natural Convection Oven

Memmert’s natural convection ovens are designed to reach temperatures up to 300°C efficient for complex processes with sensitive loads, or routine drying and sterilization tasks.

Precision-Controlled Annealing for Plastic Parts

Annealing plastic improves durability, clarity and dimensional stability by relieving internal stresses from manufacturing processes like injection molding or extrusion. Memmert annealing ovens provide consistent, programmable temperature control for plastics processing, supporting a wide range of materials including acrylic, polycarbonate and PETG.

Each unit features uniform heat distribution, high-volume chamber options and programmable controls for time, temperature and ventilation. Whether you're working with thin-walled components, molded parts or test samples, Memmert ovens help optimize product strength and finish through controlled heating and gradual cooldown.

Programmable Ovens for Every Plastic Annealing Setup

Memmert annealing ovens are available in natural convection and forced air circulation models, with volumes ranging from 32 to 1060 liters. Every unit includes a scratch-resistant stainless steel chamber, digital control interface and temperature range up to 300°C (572°F).

Available display and control options include:

- SingleDISPLAY for reliable manual setup

- TwinDISPLAY for dual-layer data feedback

- AtmoCONTROL software for advanced parameter programming

Key programmable features include temperature in °C/°F, air flap position, start time, duration, time zone adjustments and a digital countdown timer (1 minute to 99 days). Memmert annealing ovens are ideal for high-throughput labs and specialty plastics production.

Benefits of Using Memmert Ovens for Plastic Annealing

Memmert ovens offer the performance and flexibility needed to meet exacting annealing standards in industrial, medical and research settings. Key benefits include:

- Accurate temperature ramp-up and cooldown control

- Uniform heating across shelves and racks

- Hygienic stainless steel design for cleanroom compatibility

- Batch-ready capacities with fast cycle programming

- Ideal for stress relief, optical clarity and post-processing enhancement

Contact Memmert USA to find the right annealing oven for your plastic parts or production line.

Programmable Lab Equipment

Our products are equipped with AtmoCONTROL technology that has programming functions depending on which display you select:

![]()

SingleDISPLAY and TwinDISPLAY

- Manage and organize data

- Save log files in several formats

- Monitor up to 32 devices online

- Automatic alarms sent to your email when conditions are out of spec

![]()

Additional features with TwinDISPLAY

- Archive of ramps and program sequences

- Real-time view of program sequences

- Loops can be inserted within a temperature control program at any place

- Download and manage programs via Ethernet or USB