Printed Solids Case Study

Memmert is excited to share that we are partnering with Printed Solid, a US based 3D printing supply and services specialist. They are the exclusive reseller in the USA for PRUSA Research 3D printers, materials and supplies. Over the next year Printed Solid hopes to become the largest manufacturer/supplier of 3D printers and filaments in the USA.

Memmert is excited to share that we are partnering with Printed Solid, a US based 3D printing supply and services specialist. They are the exclusive reseller in the USA for PRUSA Research 3D printers, materials and supplies. Over the next year Printed Solid hopes to become the largest manufacturer/supplier of 3D printers and filaments in the USA.

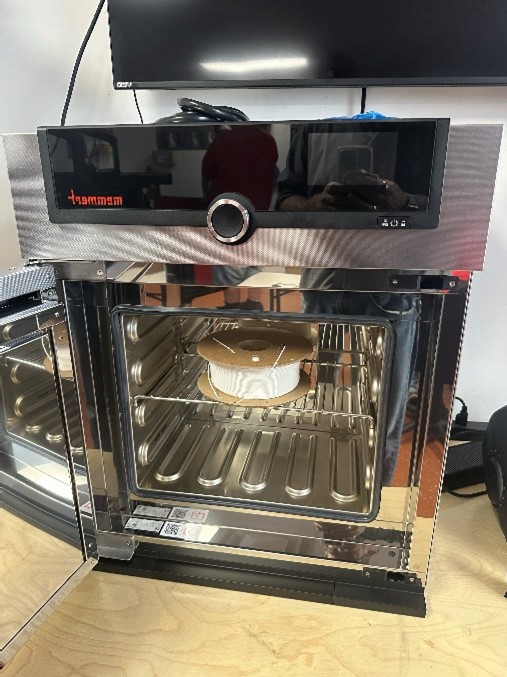

How do Memmert ovens come into play with the 3D printers you ask? 3D printers use filaments to create 3D objects from digital designs. These filaments have hygroscopic qualities meaning that they absorb moisture easily. This becomes a problem with 3D printing because as the filaments are heated within the specialty printers, moisture can be released and cause swelling, or an increase in diameter of the filament. This in turn affects the object being printed. Here is where Memmert universal ovens, like our UF 30, enter the process! To avoid this release of moisture during the printing process, the filaments are dried in one of our ovens at

130C for up to 3 hours. Once dried, the filaments are coated with a PTFE tubing to ensure they stay dry after heating and can then be fed into the printers. The 3D printing industry uses many kinds of filaments, some of which can be very expensive. To avoid damage

to this valuable product, it is essential to remove the moisture in advance to improve the quality of the printing process.

Printed Solid prefers the Memmert UF30 and UF55 models over any other brand, as they are “professional, polished looking ovens”. The fan forced circulation of the air within ensures uniform drying. With operating temperatures from 0-300C our ovens are able to accommodate any number of recommended drying protocols. Our ovens are comprised of stainless-steel chambers, that are corrosion resistant and easy to clean. Although we offer many sizes of universal ovens, the UF30 and UF55 are compact and pair easily with the Printed Solid’s amazing 3D printers.

3D printing applications are limitless, and continue to increase their presence in nearly every industry. From manufacturing, automotive, aerospace, medicine, and education, to name a few, we are happy to be a part of the process.