Determining alternative ecofriendly materials for furniture

Memmert humidity chamber HCP used for bendability tests using rapeseed stalk for bio composite material production

Crushed rapeseed (Brassica napus L.) stalk and its bendability properties were investigated in the development of new boards. For the perfect conditioning of the specimen, the Memmert humidity chamber HCP was used. Read more about this study that was published in the BioResources journal of North Carolina State University.

To learn more about HCP’s abilities and application versatility contact our experts.

Bendability and furniture production

The upsides and downsides of material bending properties are discussed in this peer-reviewed journal. These make for an argument for the eventual use of rapeseed stalk for material production. Material deflection is undesirable for typical furniture such as tabletops, cabinet shelves, side boards and more. Non-lignin and cellulose-based materials are preferred by manufacturers for bentwood furniture such as chairs and divans and other spatially wavy and curved items. Materials based outside this norm allow for greater ease in design and manufacture.

Furniture from the Bloemenwerf House, Henry van de Velde, 1895, bubinga wood, cane, ceramic - Bröhan Museum, Berlin. Courtesy of Daderot (2014).

Determining characteristics of bendability

A variety of physical attributes help measure bendability. These are force at the limit of proportionality (FE), deflection at the limit of proportionality (YE), force at the modulus of rupture (FP) and deflection at the modulus of rupture (YP). As bendability is primarily defined by thickness of material, the value can be determined as ratio of the material thickness to the minimum curve radius (Rmin) - coefficient of bendability (Kbend).

Materials for bendability which meet modern standards

There is a growing concern and implementation of ways to replace expensive materials such as wood for economic and ecological sustainability reasons. The alternative could be lignocellulosic post-harvest residues which are renewable, recyclable and sustainable (Guler et al. 2006; El-Kassas and Mourad 2013; Marinho et al. 2013).

Utilisation of rapeseed stalk as a worthy replacement

It is estimated there is approximately 2.4 trillion tons of lignocellulosic residue. This wealth of resources could be used for composite material production. A significant amount of this goes to waste by either being left on the ground or incinerated. The fibres of these residues such as flax, hemp, wheat straw, barley, rapeseed stalks and others can be more advantageous than synthetic fibre.

Rapeseed field in Unterirsingen (Zollhaus), a district of Türkheim, Germany. Courtesy of Jensibua (2013).

Use of a Memmert humidity chamber HCP for conditioning

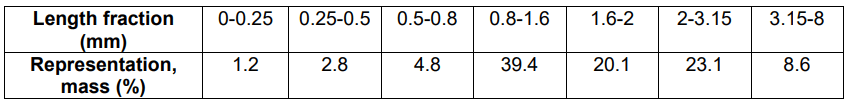

Chipboards are created from rapeseed chips. The amount used is shown in the table below.

Representation in the fractions of the chopped rapeseed straw. Courtesy of BioResources (2018).

In order to observe the effect of these modifications, boards were taken from raw, unmodified rapeseed and marked with R. The boards were 12mm thick and commercial materials were used for comparison: one was a 12-mm thick particle board (PB) (P2 for furniture use) and the second was a 12-mm thick oriented strand board (OSB) (type 3 - load-bearing board found in humid environments). DAKOTEX2600 powder was used for creating the boards. Resination was 10% and boards were pressed at a lab.

For proper conditioning of the specimen to standardised equilibrium moisture content, the researchers used the Memmert humidity chamber HCP from the climate chamber product group. The parameters were:

- 65% ± 5% RH

- 20 °C ± 2 °C

A total of 30 samples were used for each specimen set.

Conclusion to the experiment

Following the full study, the researchers found the following:

- Rapeseed residues produced new composite materials and the information gathered provided greater understanding for the thick particle board (PB) and oriented strand board (OSB)

- Rapeseed can fully replace raw materials like wood which is a more environmentally sustainable option

- The materials developed from the experiment had higher bendability values (H2O and NaOH) than commercial ones (PB an OSB). This opens up new opportunities for manufacturing furniture components which are spatially wavy and bent. Furthermore, technological modifications and advancements can be made on properties of the rapeseed boards

- Overall, such renewable raw materials produced biocomposites with bending qualities which meet the standards of modern design and production

About the Memmert HCP

In addition to these applications, the Memmert humidity chamber HCP is renowned for its technologically advanced characteristics, high quality, unique form, reliable handling, accurate monitoring and safety features as well as a wide versatility of applications.